It has been a long time since I posted here. Let's see how it goes.

I recently have the pleasure of giving a Talk at the TedxBoise event several weeks ago. The name of my talk "What to do with a giant 3D Printing Farm." I will post the video when it is dropped but the talk was primarily about how I came to be so heavily involved with 3D printing over the last 1-2 years, after having dismissed it for most of my career.

I'm going to take this post to summarize and clarify some aspects that of 3D printing that I wasn't able to speak about. Hopefully this post will be a complementary resource to the video when it drops.

So what do I think of 3D printing? It is a ridiculous personal technology. Owning a personal 3D printer is like owning a personal Bandsaw. Everyone can use them, very few can use them well because it actually does require skill. Personal 3D printing is a failed idea, because physics and the non-scientific way that it was created makes it impossible to have the reliability that a home appliance needs. To show this let me ask you a question. When was the last time you replaced a non-disposable component of one of your appliances. The faucet on your sink? The rotor in your Dishwasher? The most involved with the appliances we use is in replacing the capsule in a Keurig or the cartridge in our Paper Printer. But a 3D printer will have a nozzle clog, because physics, and when that happens you have to identify the problem and then have the tools and wherewithall to replace the nozzle. That disqualifies personal 3D printing as a personal technology. And no amount of software will ever prevent a nozzle from clogging. I will leave that there. I could go on, but my beef with personal printing is long and comprehensive.

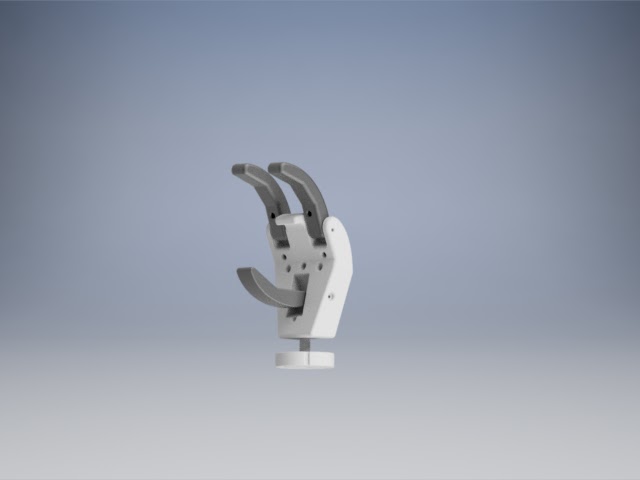

The requirement of 3D printing of skill to operate it means that utilization of 3D Printing by regular people will be through services. Shapeways, 3D Hubs, etc. But through several projects that I was involved in I found that one service of 3D printing was missing. Production.

Since 3D Printing is a digital process with nearly no geometry constraints it can be used to make almost any piece of hardware. Now most will counter that statement with 3 basic arguments. 3D printing is Slow, Crappy, and Expensive. These are actually the core of my Tedx Talk so, to avoid spoilers at this point, suffice it to say that each of these are wrong and have been proven wrong by one of the largest 3D printing factories on the planet that I have the pleasure to be a founder of.

3D printing is a viable production method. But it is only viable up to a certain point. On average at Slant 3D production with 3D printing is more affordable than injection molding up to about 20,000 parts (give or take). We plan to make it cheaper up to 100,000 or more. At that point the capital expenditure that makes molding prohibitive basically drops away in the scale. The cost of the part is in the cost of the material and the energy that goes to making it. Oddly this is true of 3D printing. So once there are facilities large enough to produce millions of pieces with printing, there will be no reason to use molding.

The caveat there is that molding is reliable and very fast at very high volumes. I don't think that printing will ever replace it at that scale. But it will start absorbing the low volume production of startups and inventors. The digital nature of it lets inventors design and iterate on 10 different version of a product for very little cost. The same way you would with software. This hasn't quite become mainstream yet because there are really only a 2-3 companies in the world with the 3D printing capacity to take a design from prototype to production entirely with printing. Slant 3D is one of them.

But as 3D Printing manufacturing becomes more mainstream I believe that large scale production will decrease and be supplanted by niche products. Note niche here does not mean ultra-customized. Customization is also a black hole. But niche markets of several thousand clients. As more people come into this space the need for "homerun" products will decrease and the production methods to create them will not be as necessary. Only truly ubiquitous products would be created with mass production. Phones, lights, clothes. But toys, tools, accessories can all parsed out to individual groups and produced with giant 3D printing farms.

3D Printing is the future of "

manufacturing" not the future of personal manufacturing, Amazon same day delivery invalidates that. But Amazon will always need new products to delivery.

The work we're doing at Slant 3D for the entrepreneur in the dorm room with a CAD program not a compiler.

_______________________________________

Its good write again. I think I will do this more often. I have had several writing projects on hold, I think I will be able to get back to them.